Best Bandsaw Blades for your Portable Sawmill

Struggling to figure out which are the best blades for your setup and milling needs? Let's go over the basics of blade quality

You want the best bandsaw blade on your sawmill so you achieve a very smooth cut each time, easily milling your logs into boards.

But what are the best blades for getting straight cuts, and what blade length do you need to purchase? Included in this guide are the basics on how to choose good quality bandsaw blades.

Bandsaw Blade Basics

Bandsaw blades are flexible loops of metal with sharp teeth on one side, designed to quickly cut through wood. Regular workshop bandsaws can be used for cutting curves or straight lines, and can easily cut soft woods or hardwoods into complex shapes.

Portable sawmills are a different beast, but a powerful one, which can easily turn a log into a series of boards or slabs for your woodworking needs.

But how do bandsaw blades work? Let's go over the components of these blades to find out:

Tooth Blade

The teeth on a bandsaw blade are specifically designed to cut through wood, either softwoods or hardwoods. With each pass the teeth cut away a small amount of material from the wood. That wasted material becomes sawdust and is known as the Kerf.

One of the benefits of bandsaw mills is that they have a small kerf, so less material goes to waste.

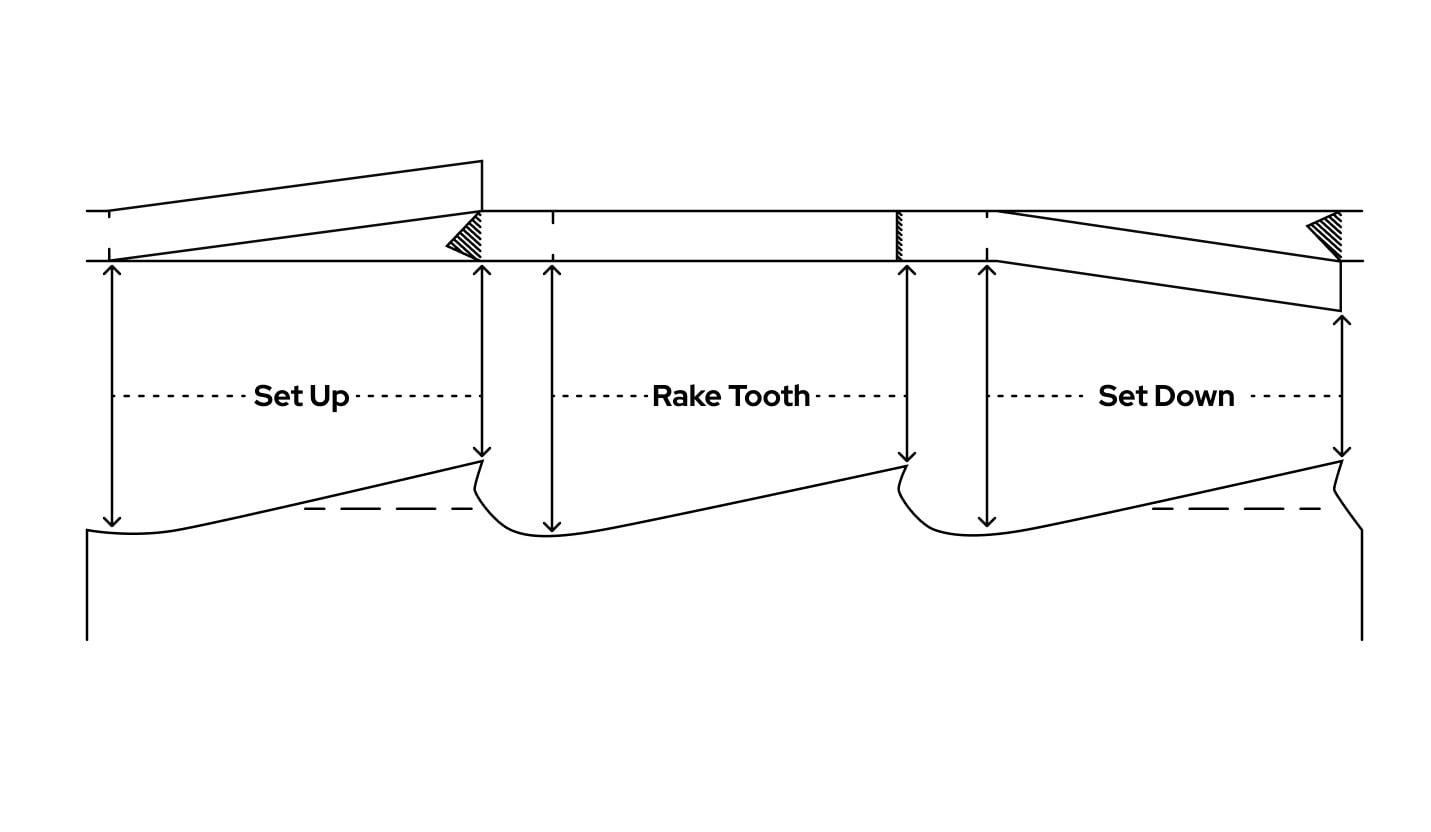

Bandsaw blades also have a Set, which is a repeating pattern of three teeth.

-

-

One tooth is set to the left of the blade

-

One tooth is centered with the blade, known as the Rake Tooth

-

One tooth is set to the right of the blade

-

This tooth configuration helps with efficient cutting. Other blades without a strong set may leave marks on your wood or fail to do straight cuts.

Hook Angle

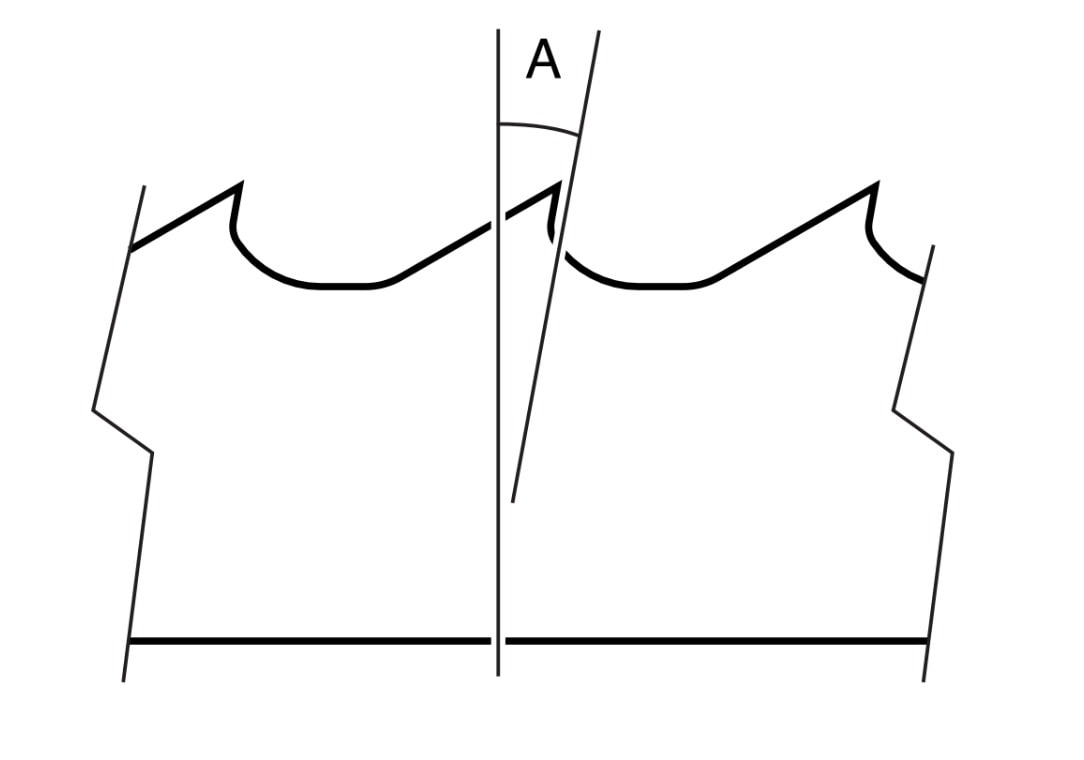

Bandsaw blades are also designed with a specific tooth angle, which is ideal for cutting into different species of wood.

There are several common adjustments to the hook angle to make them stand out from standard blades:

-

-

7° for frozen timber or hardwoods

-

10° for general use

-

14° for softwoods

-

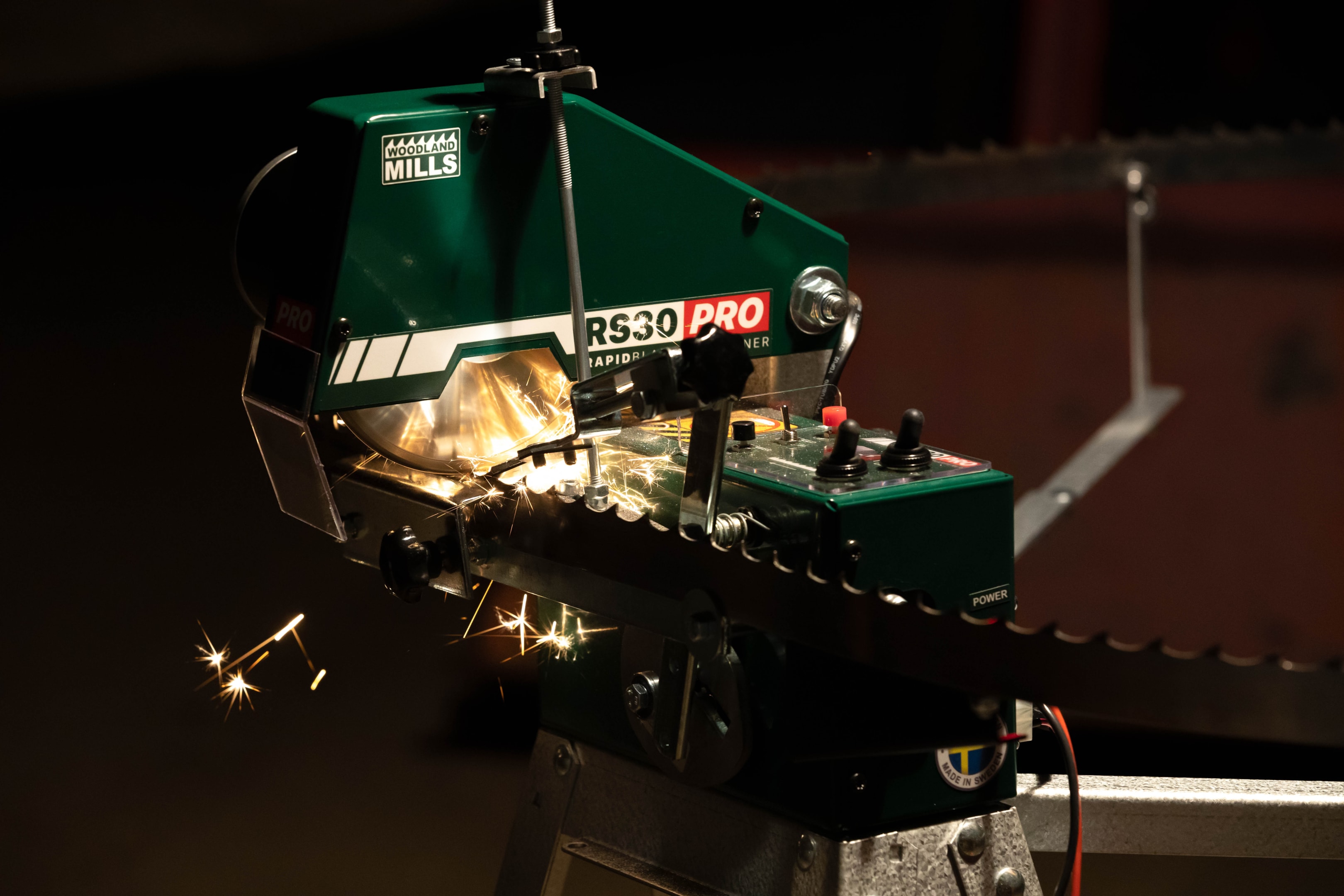

If you own a bandsaw blade sharpener you can easily adjust the hook angle yourself, making it so you have the best blades, whether you're cutting dry wood, something newer and greener or hard exotics.

You can have one blade that does everything, or several blades adjusted to do different types of cutting.

Tooth Face

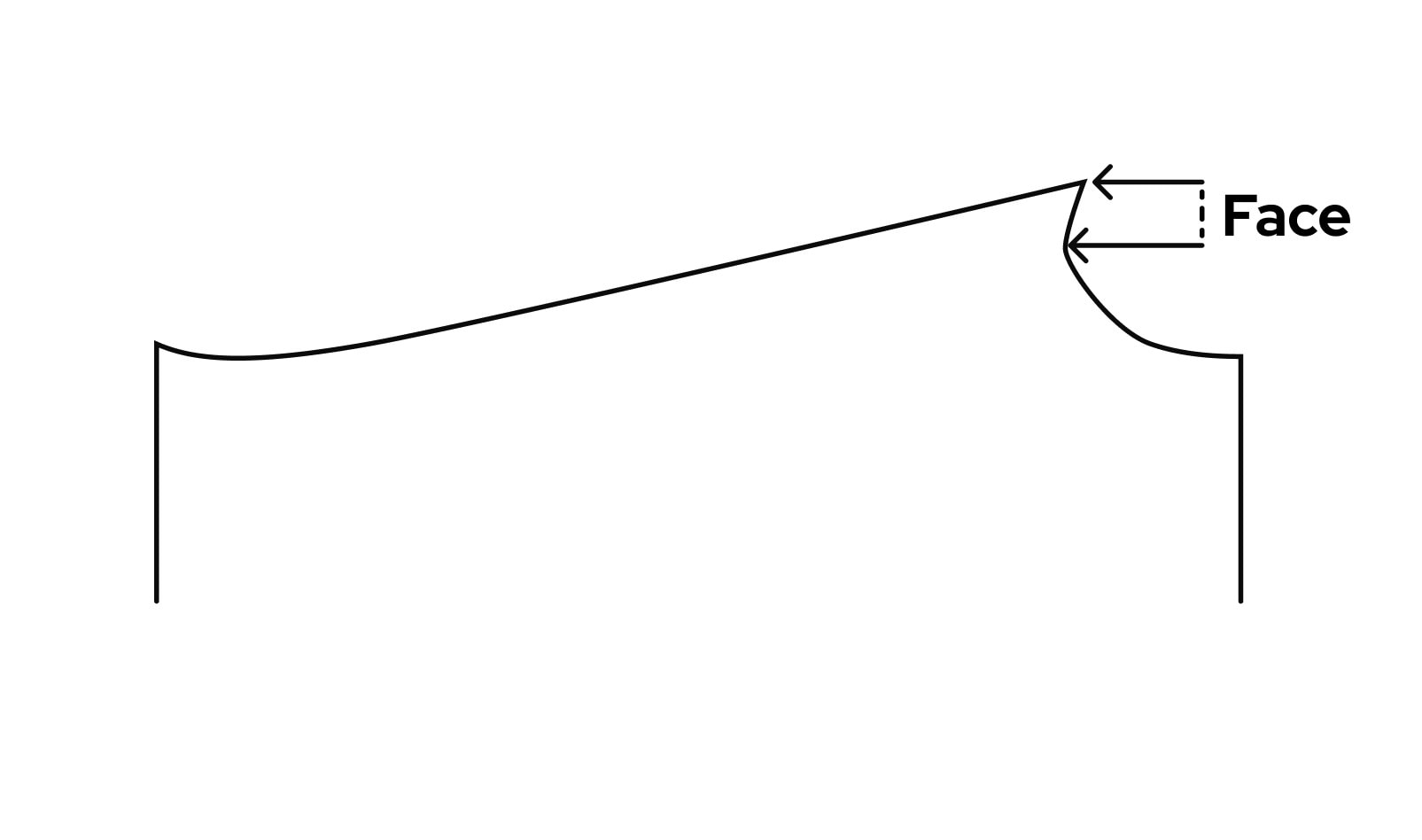

The face of the tooth is the sharp, cutting blade. This is the part which has been sharpened in the factory, and that needs to be resharpened to put the cutting edge back in your blade.

While you could buy a new blade, why not sharpen your existing blade to put new life back into it?

It's important when sharpening the tooth face that your grinding disc follows it along into the gullet, the gap between the teeth. This helps to grind down wear points in the blade and prevent breaks, even though it's only removing a fraction of an inch of material.

What's the right size of bandsaw blade?

Different sawmills require different sizes of bandsaw blades. For example

Woodland Mills HM122 Portable Sawmills:

-

-

7/8” Pitch - 125″ x 1.25″ x 0.042″ x 7/8″ (3175mm x 32mm x 1mm x 22mm) for Hard and Softwoods

-

3/4” Pitch - 125″ x 1.25″ x 0.042″ x 3/4″ (3175mm x 32mm x 1mm x 19mm) for Hardwoods

-

Woodland Mills HM126 and HM130 Portable Sawmills:

-

-

7/8” Pitch - 144″ x 1.25″ x 0.042″ x 7/8″ (3658mm x 32mm x 1mm x 22mm) for Hard and Softwoods

-

3/4” Pitch - 144″ x 1.25″ x 0.042″ x 3/4″ (3658mm x 32mm x 1mm x 19mm) for Hardwoods

-

Woodland Mills HM130MAX Portable Sawmills:

-

-

7/8” Pitch - 157.5″ x 1.25″ x 0.042″ x 7/8″ (4000mm x 32mm x 1mm x 22mm) for Hard and Softwoods

-

3/4” Pitch - 157.5″ x 1.25″ x 0.042″ x 3/4″ (4000mm x 32mm x 1mm x 19mm) for Hardwoods

-

Woodland Mills HM136MAX Portable Sawmills:

-

-

7/8" Pitch - 173″ x 1.25″ x 0.042″ x 7/8″ (4394 mm x 32 mm x 1 mm x 22 mm) for Hard and Softwoods

-

3/4" Pitch - 173″ x 1.25″ x 0.042″ x 3/4″ (4394 mm x 32 mm x 1 mm x 19 mm) for Hardwoods

-

The Best Bandsaw Blade for You?

The best blades for your bandsaw mill have the following aspects:

-

-

Are the correct size for your mill

-

Can easily be resharpened to restore the blade

-

Has the right specifications for the wood in your log pile

-

Fits in your budget

-

Keep these tips in mind and your sawmill will have the best cutting ability every time you use it.

How to Keep Your Bandsaw Blades in Top Shape

Follow these steps to ensure your saw blades maintain their cutting power.

Do:

-

-

Maintain a steady and consistent speed while milling

-

Keep an eye out for nails or any metal objects hidden inside your wood

-

Replace the blade on your bandsaw mill when it begins to dull and resharpen before reusing it

-

Properly grind the tooth and the gullet when sharpening

-

Consider getting a Tooth Setter to restore the set to your teeth or even give it an extra set

-

Don't:

-

-

Use a blade once it's become dull, as this will result in poor quality cuts

-

Alter or modify the blade in any way, such as by attempting to weld broken teeth back on

-

Use fluids other than water and dish soap in your lubrication tank, as other substances could cause damage to the blades or belts

-

Tips for Getting the Most from your Bandsaw Blade

Always ensure you are operating your sawmill according to best practices and following all steps laid out in the owner's manual. Some general advice for running your mill and getting the most from your blades includes:

-

-

Always ensure you're using the right amount of blade tension. The correct tension is to turn the tension handle so it's snug, then turn 2.5 to 3 times, ensuring you always have good tension

-

Make sure your blades are always sharp. If you start having difficulty pushing your blade through the log or notice wavy cuts, sharpen your blade or use a fresh one to ensure straight cuts

-

A general purpose blade will get you through most situations but if you're routinely milling hardwoods or more abrasive species then try a blade with a different pitch angle

-

If your blade starts to build with pitch, use your lubrication tank to help remove the pitch and guarantee a clean cut

-

SHOP SAWMILLS

HM122

The HM122 portable sawmill, packaged with the rugged Bushlander® trailer for complete mobility, loaded with features like the RapidChange® blade system, auto lube and more.

HM126

The sawyer favourite HM126 portable sawmill, packaged with the Woodlander® trailer for complete mobility, ideal operation height and easy storage.

HM130MAX®

The wide capacity HM130MAX® portable sawmill, packaged with the Woodlander® trailer for complete mobility, comfortable operation height and easy storage.

HM136MAX™

Our widest-capacity portable sawmill, the HM136MAX™, packaged with the Woodlander® trailer to make it easy to take anywhere and easy to store.

Join the Woodland Mills Community Facebook group. Search advice and insights from over 65,000 knowledgeable, supportive members.

- Pre-purchase considerations

- Sawmill set-up support

- Project inspiration photos and videos

- Community troubleshooting support