What does a wood chipper do?

We explain the mechanisms of how wood chippers work and how wood chips are a great byproduct to use

A wood chipper transforms tree limbs, branches, and wood debris into small, uniform chips.

These heavy duty machines excel at processing pruned branches, storm-damaged tree limbs and cleared brush, converting raw wood waste into manageable material, making cleanup and debris management easier. Larger wood chippers can even turn whole trees into mulch within seconds.

What's more, is that the waste material from a wood chipper can be a useful gardening and landscaping tool, giving wood chippers even more utility around your property. Investing in new equipment can be daunting, so let's break down how these machines work.

Understanding the basics of a wood chipper

Wood chippers come in different configurations to suit various needs and equipment setups.

These machines are typically powered a few different ways. A PTO (Power Take-Off) wood chipper uses your tractor's power to process wood materials through a cutting mechanism. A gas-powered wood chipper uses an engine as its power source, offering standalone operation and portable convenience.

Here's how they work:

Infeed chute: The machine's operator inserts tree branches, brush or other organic materials into the infeed chute opening, where it is either fed directly into the chipping mechanism or into the infeed rollers.

Infeed system: In a chipper with a hydraulic infeed system, the infeed roller pulls the material into the flywheel to be chipped. These rollers can be adjusted to change the infeed speed to best chip branches no matter the size.

Chipping mechanism: In a disk chipper, a steel disk rotates at rapid speeds with cutting blades attached to it. As the material is fed into this flywheel, it is rapidly chipped away. Chipped material passes through the flywheel and onto paddles that discharge the material out of the chipper.

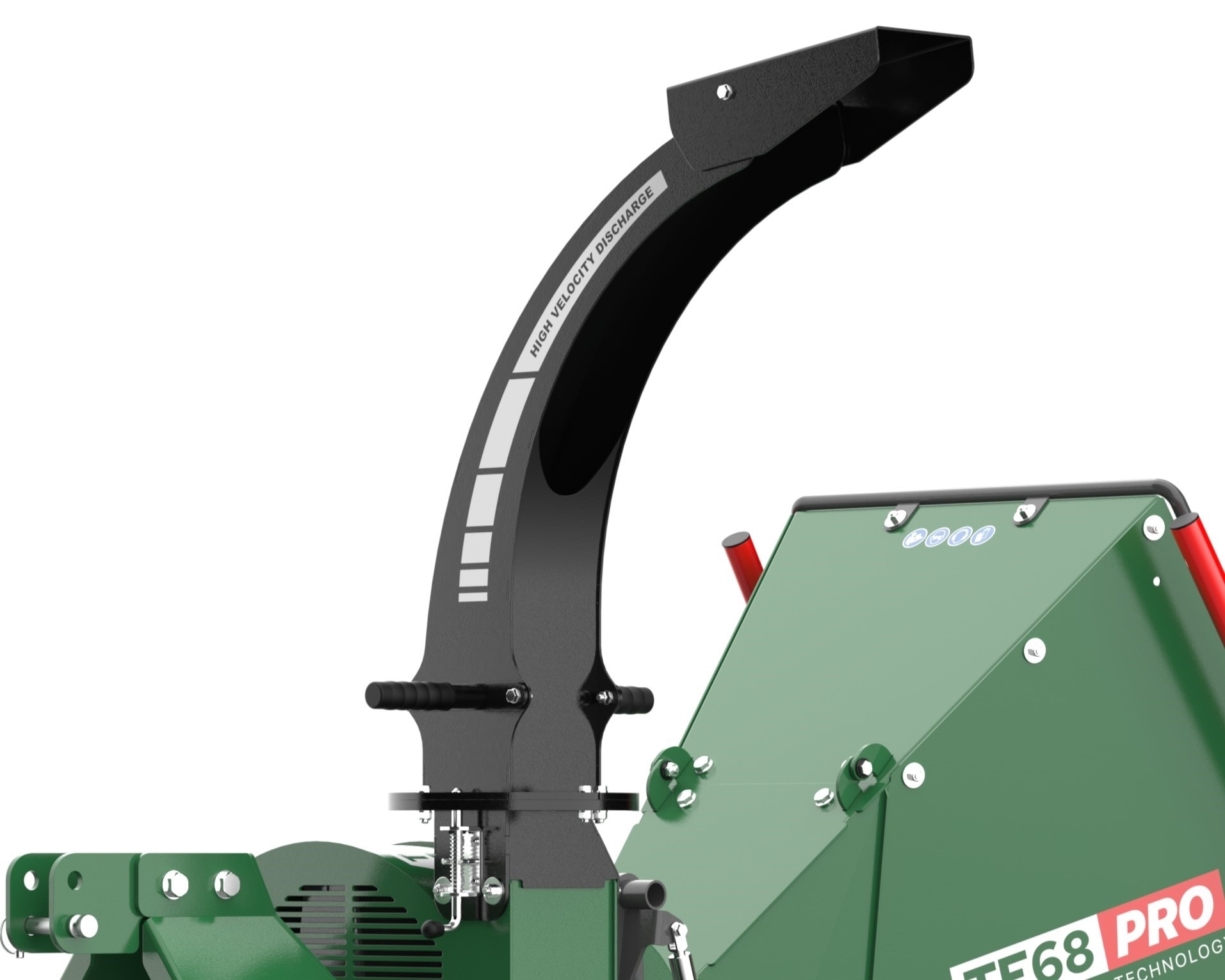

Discharge chute: An adjustable 360-degree chute throws the wood chips out, where they can be collected in a trailer or left on the ground.

Twin Flywheel Wood Chippers

There are some differences between some models of chippers. Many of Woodland Mills' models use infeed rollers, which grab onto and draw material into the spinning flywheel.

Meanwhile other models, like the TFG55 models, are gravity infeed systems, which rely on the weight of the material and the angle of the chute to feed the branches into the flywheel.

The PRO Series of chippers, the TF46 PRO, TF68 PRO, TF810 PRO as well as the TFG55 models, also feature Twin Flywheel technology. This Woodland Mills original chipper design uses a second flywheel to assist the first by helping to eject leafy and airy materials into the discharge chute, making it easier to chip leafier materials.

Twin Flywheel is a revolutionary wood chipping technology only available on Woodland Mills chippers.

There are also drum chippers, which use a rotating drum to chip materials as well. Large-scale commercial wood chippers are essentially whole tree chippers and can quickly turn smaller trunks into a large pile of wood chips. The downside to these chippers is that they're considerably more expensive and outside of the budget of many acreage owners.

Primary uses of a wood chipper

Wood chippers serve multiple essential functions for property maintenance and land management. Understanding these applications helps maximize the value of your investment in a tree chipper.

Tree and branch disposal

Wood chippers excel at processing various types of woody material. They can handle both soft and hard branches efficiently, turning them into manageable wood chips.

-

-

Hard branches from oak and maple trees

-

Pruned limbs from routine maintenance

-

Storm-damaged branches

-

Tree disposal

-

Orchard pruning waste

-

Lots of landowners have organic waste like tree branches, brush or shrubbery on their property which needs to be removed. A wood chipper can help turn that waste material into a useful resource for your property.

Clearing land for new projects

Wood chippers can quickly process cleared vegetation, making site preparation more efficient and organized. They prove invaluable when preparing land for:

-

-

New construction sites

-

Agricultural expansions

-

Trail development

-

Fence line clearing

-

Property boundary maintenance

-

A wood chipper can help turn forestry waste into manageable pieces so it can be hauled away or used for landscaping elsewhere. You can even use it as fuel by burning it, if you want.

Creating mulch

Wood chippers transform raw material into useful wood chips for:

-

-

Landscaping projects

-

Garden pathways

-

Erosion control

-

Weed suppression

-

Property maintenance

-

Wood chips can be a great tool to retain moisture in a garden or control soil temperature. What's great about this is that wood chips will become compost over time, adding to the soil base.

Benefits of using a wood chipper

Efficient wood processing delivers significant time savings. It can reduce manual cutting, handling and transportation, speed cleanup operations and streamline tree limb disposal.

Depending on the size and horsepower of your chipper, you can go from chipping tree branches and other organic waste, to chipping away an entire tree in seconds. Make sure your tractor has the horsepower and weight to support these tree chippers, but if it does, it can make cleaning up your property an easy and quick task.

Depending on your reasons for buying a chipper, there are smaller models or more powerful machines able to chip whatever size of material you need.

Here are just a few of the reasons why you should consider getting a chipper to get rid of your tree branches and other yard waste:

Cost-effective waste management

Wood chippers provide economic advantages through reduced disposal fees, lower transportation costs and on-site material processing. This may lead to decreased labor requirements and long-term environmental benefits

Using a wood chipper supports environmental stewardship by eliminating burn piles, creating useful materials from waste and reducing landfill usage. Wood chipping also supports natural decomposition and promotes sustainable practices.

Why every landowner needs a wood chipper

Investing in a quality wood chipper transforms property maintenance from a challenging task into an efficient, manageable operation. A wood chipper isn't just another piece of equipment. It's an investment in efficient, sustainable property management that can improve productivity, reduce costs and provide lasting environmental benefits.

Frequently Asked Questions

What is the point of a PTO wood chipper?

A PTO wood chipper efficiently processes woody debris using your tractor's power, eliminating the need for a separate engine and reducing maintenance requirements.

Are wood chippers worth it?

For landowners who regularly maintain wooded properties or need to clear brush, a tree chipper can significantly reduce labor costs and time spent on debris management.

How do PTO wood chippers work?

PTO wood chippers connect to your tractor's power take-off shaft, using the tractor's engine power to rotate cutting blades that process wood into chips. The material feeds through rollers into the cutting mechanism and exits through the discharge chute.

How do gas powered wood chippers work?

Gas-powered wood chippers use an internal combustion engine to drive the cutting mechanism. Material enters through the gravity-assist infeed chute, sharp blades mounted on the flywheels create clean cuts, and processed material exits through the discharge chute.

What can you do with wood chips?

Wood chips are an effective landscaping and gardening resource which can serve many different purposes. You can use it as a soft padding for your childrens' play structures, or use it as the bed to your garden. Some sawyers use it to create pathways throughout their property, suppress weeds, or use them for more specialized purposes, like growing and harvesting mushrooms.

Regardless on your plan for the wood chips, they are a great byproduct from the wood chipping process and can serve a multitude of purposes.

How do Twin Flywheel wood chippers work?

A Twin Flywheel chipper separates a chipper's two main functions, chipping and throwing. The chipping flywheel spins with high torque for increased chipping power, and the secondary flywheel spins at twice the speed, to discharge materials faster and farther.

SHOP WOOD CHIPPERS

WC46 4" PTO

The WC46 chipper has a chipping diameter up to 4". It's designed for tractors with 15-30 HP at PTO and features an auto-hydraulic infeed system and 360-degree swivel discharge.

WC68 6" PTO

The WC68 chipper has a chipping diameter up to 6". It's designed for tractors with 20-50 HP at PTO and features an auto-hydraulic infeed system and 360-degree swivel discharge.

WC88 8" PTO

The WC88 chipper has a chipping diameter up to 8". It's designed for tractors with 35-100+ HP at PTO and features heavy-duty construction and an auto-hydraulic infeed system.

TF810 PRO PTO

The TF810 PRO chipper features our patented Twin Flywheel Technology. Designed for tractors with 35-100+ HP at PTO, it has a chipping diameter up to 8" and auto-hydraulic infeed system.

Join the Woodland Mills Community Facebook group. Search advice and insights from over 65,000 knowledgeable, supportive members.

- Pre-purchase considerations

- Sawmill set-up support

- Project inspiration photos and videos

- Community troubleshooting support